TRASH INTO CASH !

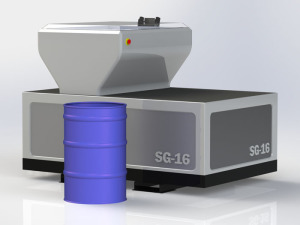

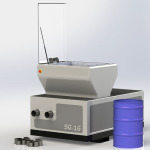

SG-16 Briquetting machine

SG-16 briquetting machine has high quality and it is the result of a long research and development process. The machine works automatically and controls its own functions. It is a good and environmental-friendly solution for processing and refining different kinds of bulky materials.

Applications:

-Briquetting of metallic chips

Lots of metallic chips are generated during machining. The chips take a lot of space and absorb cutting fluids. According to current environmental legislation the chips must be stored in tight containers to be protected from the rain. After pressing the metallic chips to briquettes they are easier to handle, store and transport in much more cost effective way. All the hazardous cutting fluids are pressed out from the chips during the briquetting phase and they are taken to the machine’s fluid container to be reused in the machine tool for minimizing the loss of cutting fluids.

Briquettes can also be re-melted, which reduces the fire losses in melting process compared to separate chips. Furthermore the charging the oven is faster.

-Package waste

Lots of carton board-, paper- and wood waste is generated in facilities where big amounts of packages are handled. This takes a lot of space as well. With our briquetting machine also these materials can be briquetted which helps to save storing space and the usage of big dumpsters can be avoided. Briquettes are also an excellent fuel for waste incinerators and their transportation and storing is easy.

-Straw

Straw that is collected from the fields during the threshing of the crops can also be briquetted. Straw briquette has a high heating value and it also has much higher monetary value compared to typical straw bale.

-Demolition waste

The particle board-, paper-, plastic- and wood waste from the construction demolition work can also be briquetted. Furthermore the transportation and storage is much more easier and economical.

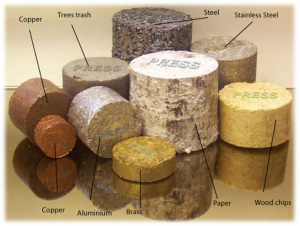

Tested materials:

- steel chips

- copper

- aluminum

- stainless steel

- waltz dandruff

- cast iron

- sanding dust

- cutting waste (steel)

- plastic

- rubber

- car tires

- computer waste

- demolition waste

- wood

- branches

- cutting waste (wood)

- planer shavings

- paper

- cardboard

- styrofoam

- cloth

- park waste

- feather

- grass

- straw

- reed

- sugar cane

- chicken manure

- horse manure

- wheat

- etc…

Steel briquetting

SG-16 for machine industry producing metal chips.

Compress the metal chips into briquettes.

Make storage and transportation easier.

Re-use lubricants in the chips.

Sell metal back to refinery.

Briquettes minimize oxidation and slag

With less surface area the oxidation and slag formation in the briquettes is much less than in the chips.

Briquettes are drier than chips

Compressing the chips will remove liquid so melters will pay more for the re-cycled material.

Briquettes are easier to handle

Transporting scrap to the furnace, as well as scrap inside a furnace. It is easier to pick up blocks than chips.

Recover lubricants and coolants

Briquetting process will squeeze out from the chips your precious lubricants and coolants for re-use.

Accessories

- Chip conveyors

- Shredders

- Crushers

- Pre-washers

- Coolant and lubricant filter systems

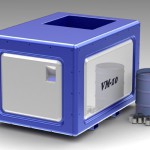

LD dust, from hazardous waste to reusable raw material.

200 litres of grinding waste from a gearwheel (= 100 % hazardous waste).

After briquetting the grinding waste there is 32 kilograms of recyclable raw material and 58 litres of grinding oil which can be reused (= 0 % hazardous waste).

1. Metallic chips from the finishing work are very difficult to handle.

2. The metallic chips pile shown in the previous picture after briquetting it.

1. Metallic chips from the drilling machine before briquetting.

2. The metallic chips pile shown in the previous picture after briquetting it.

1. Metallic chips from the processing centre before briquetting.

2. The metallic chips pile shown in the previous picture after briquetting it.

Gallery